MULTI-JACKBOLT TENSIONING

Superbolt multi-jackbolt tensioners (MJTs) take the high preload requirements in large diameter bolting and break it down into manageable torques using the jackbolts threaded through the nut body.

How it works

- By tightening the jackbolts, a strong thrust (axial) force is generated and directed against a hardened washer

- The loads are transferred through the nut body, which is positioned on the main thread by hand

- A hardened washer is used to transfer the force while protecting the flange face

- The thrust (axial) force of many jackbolts and the opposite reaction force of the main bolt head create a strong clamping force on the flange

- The thrust (axial) force from the jackbolt creates an equally strong reaction force in the main bolt

Advantages

- Tremendous clamping force available

- Low torque requirement – only hand tools needed

- Safe method for installation personnel

- Quick installation and removal

- Tightens stud/bolts using pure tension

- Tensioner flexibility adds elasticity to studs/bolts to create a better bolted joint

- Fits in restricted areas

- Provides even tension from stud to stud

- Accurate within 10% of specified bolt tension

Application

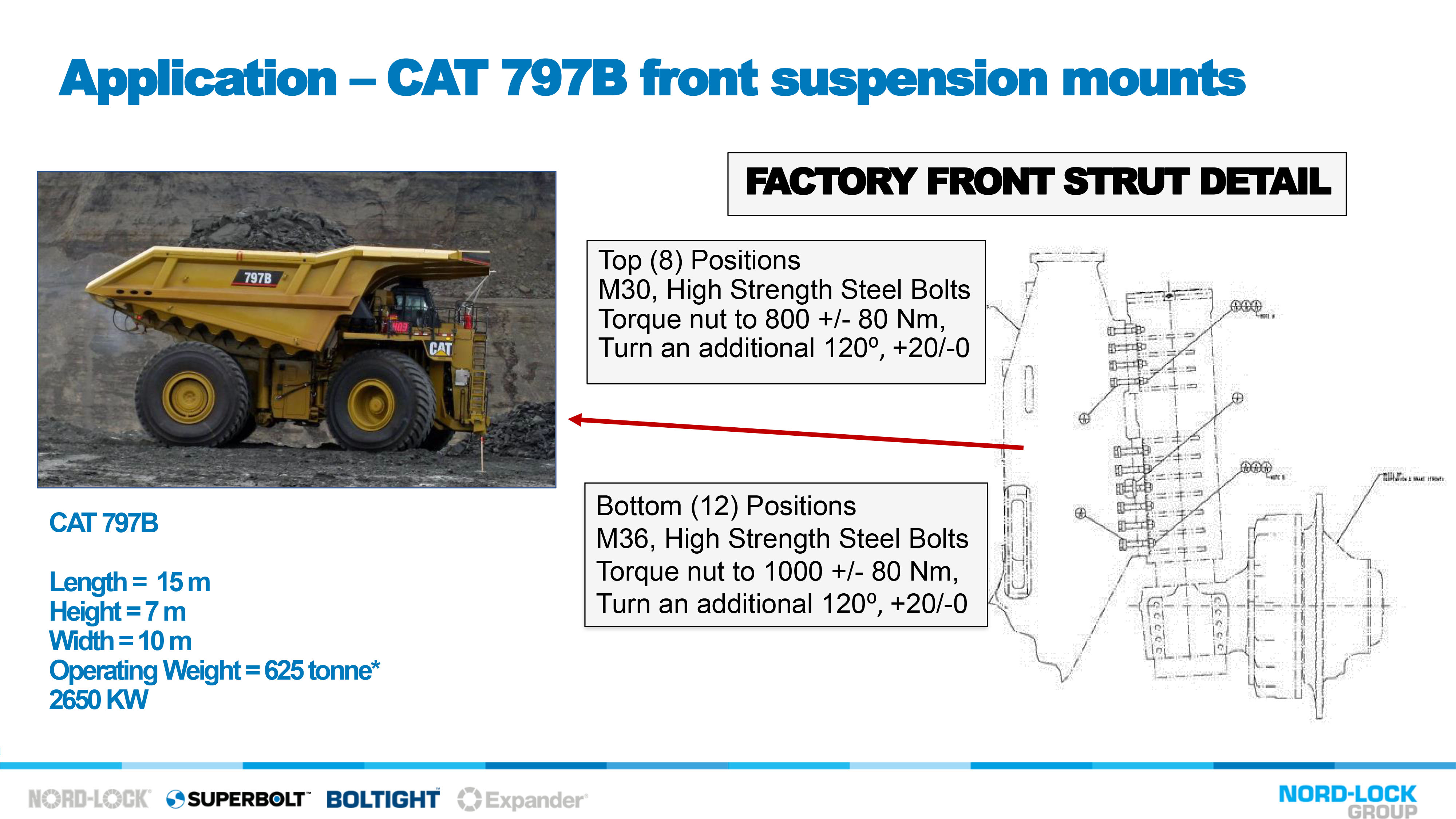

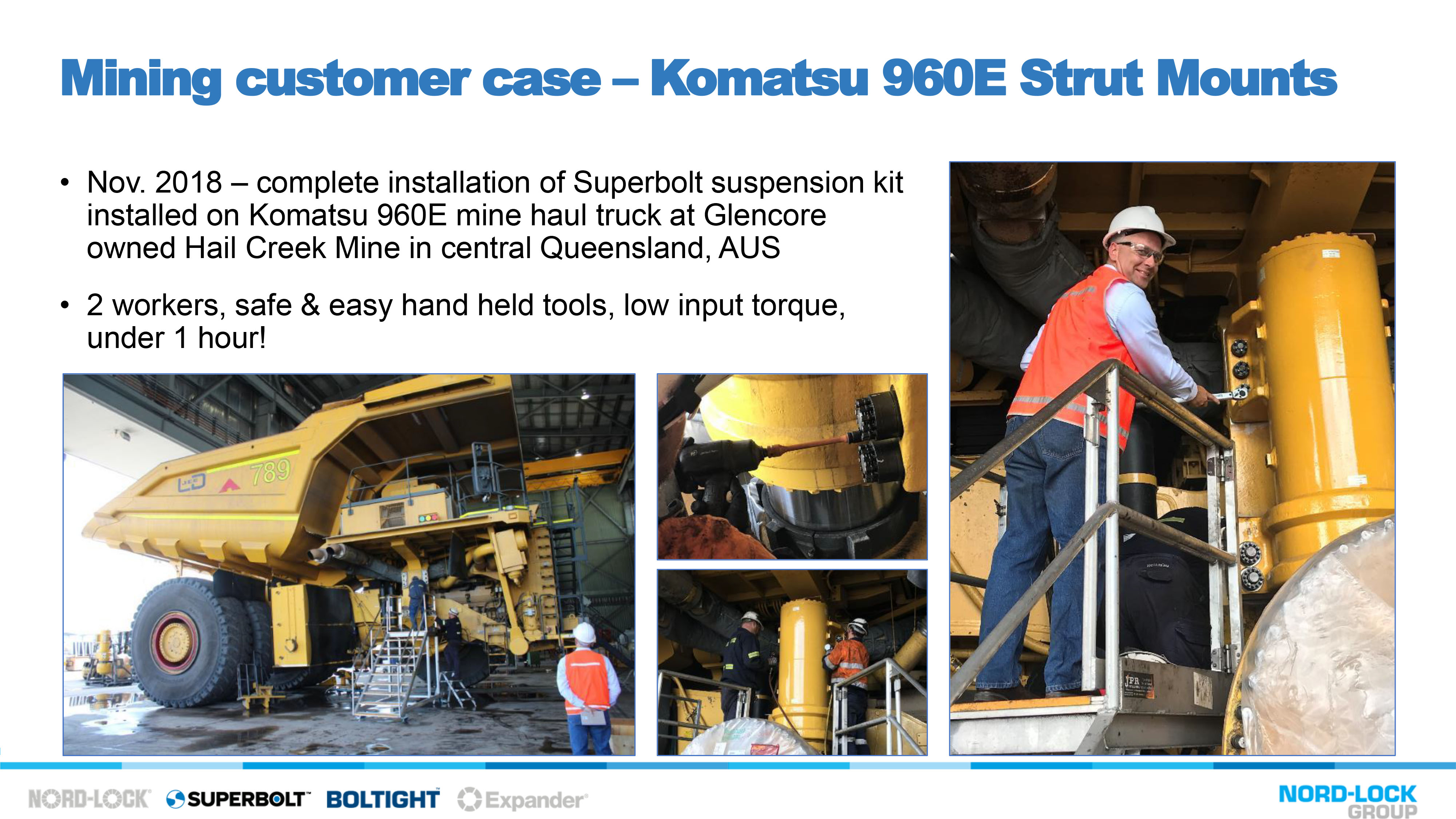

Caterpillar & Komatsu Mine Haul Truck Front Suspension bolt

Metalurgy industry

Gas and pipeline bolting

Suspension bolt

SOLUTIONS FOR HEAVY MINING EQUIPMENT

Nord-Lock give you LIFE TIME WARRANTY

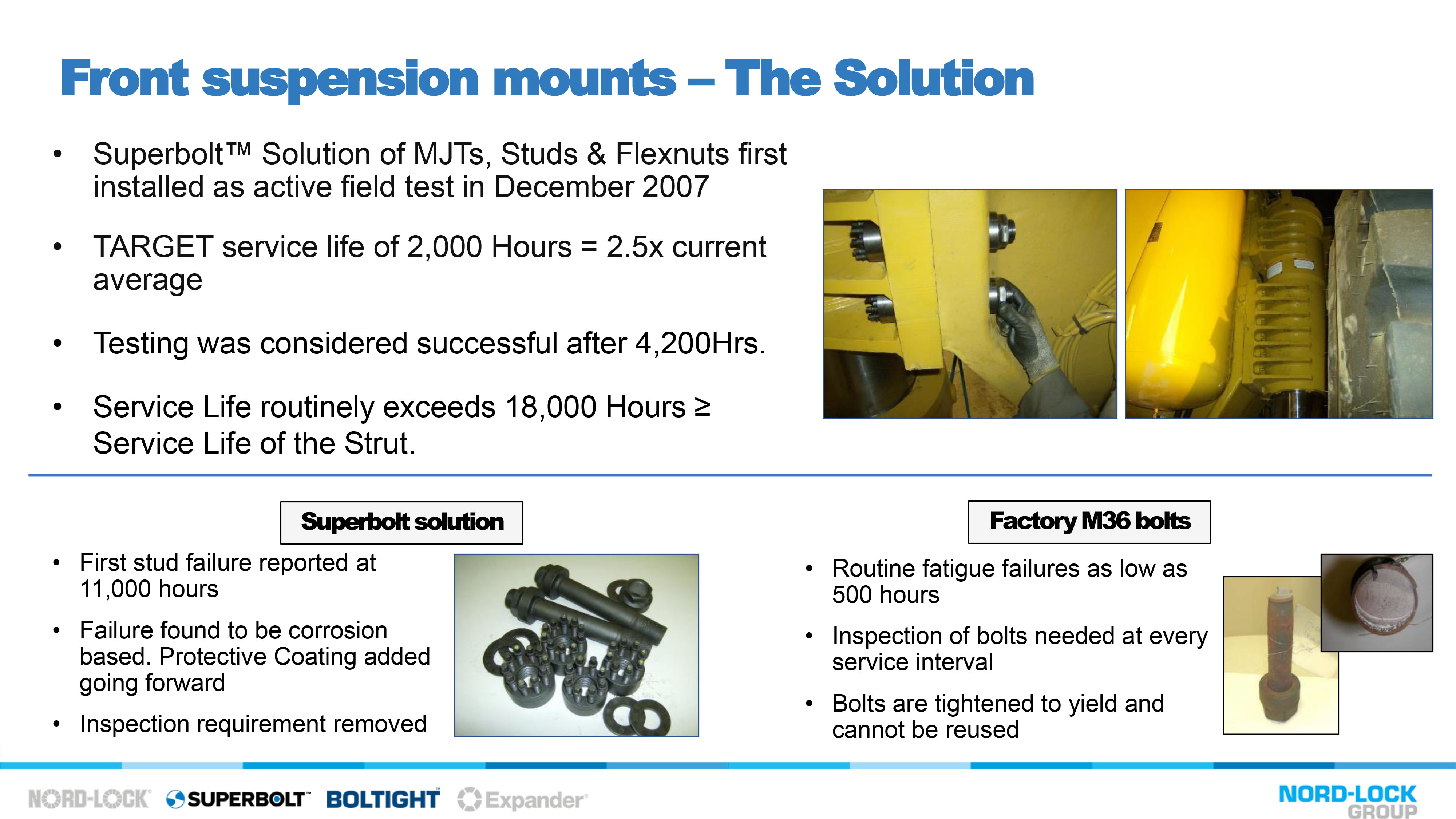

Front suspension mounts

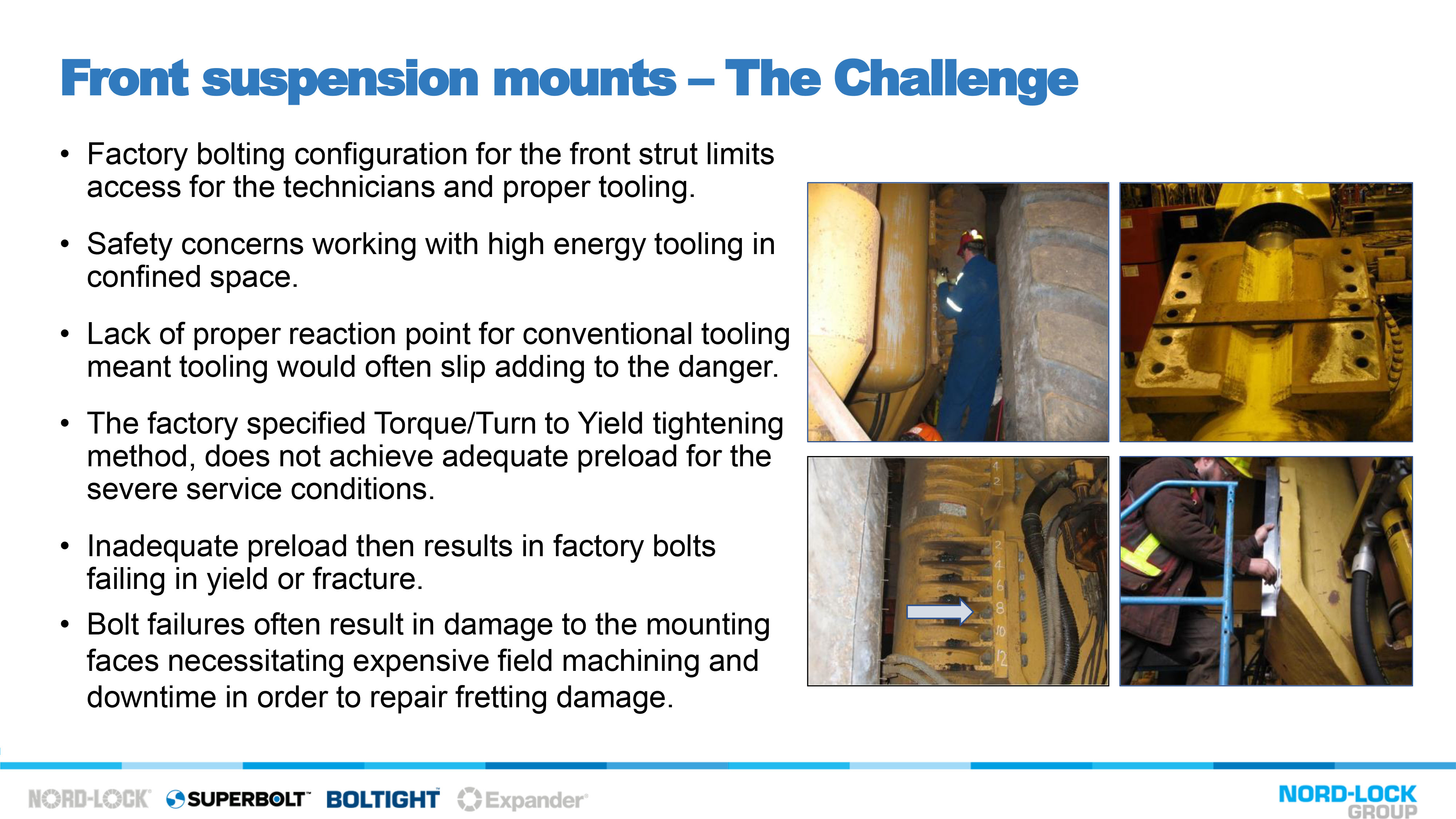

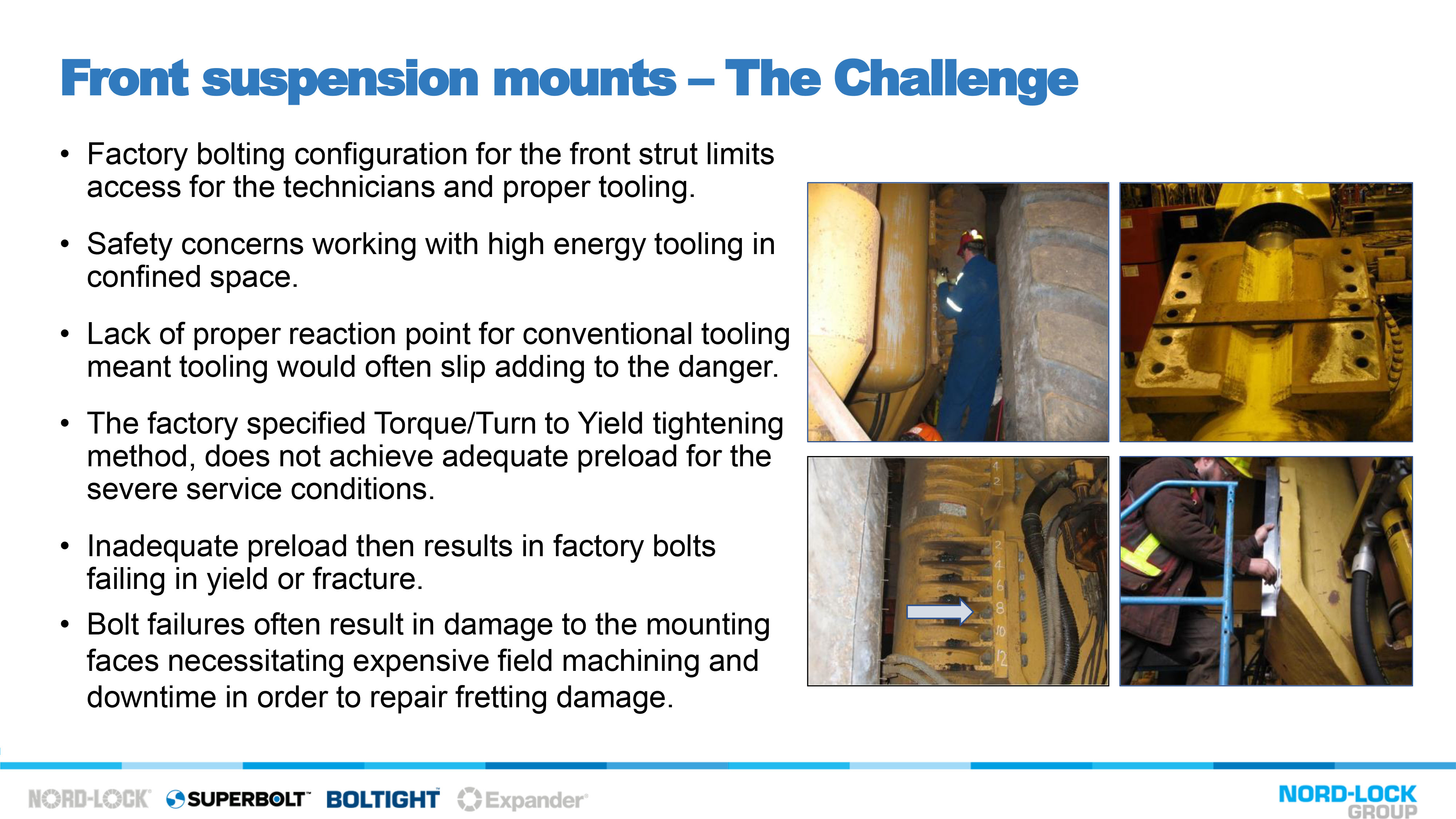

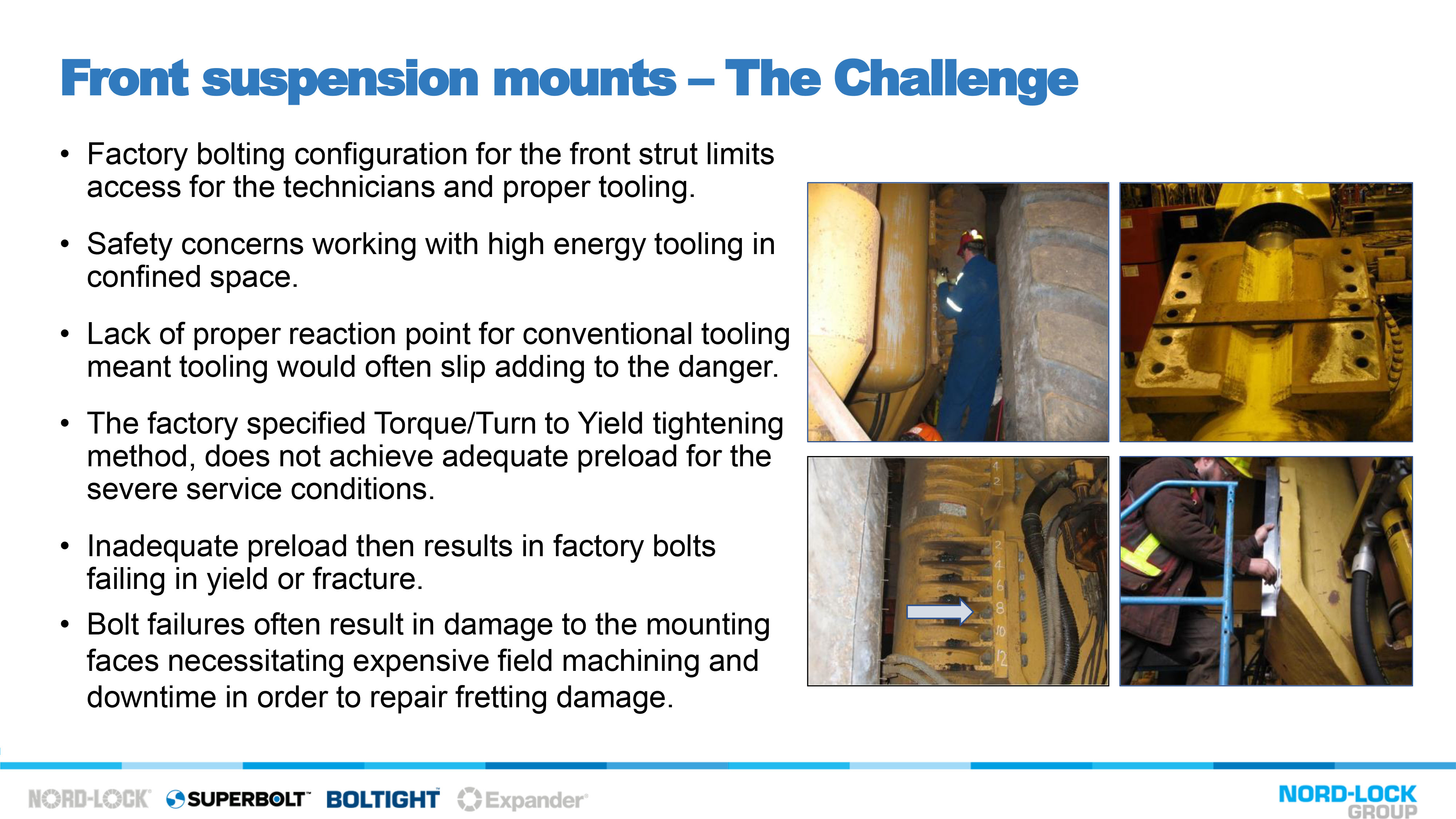

Factory bolting configuration for the front strut limits access for the technicians and proper tooling.

• Safety concerns working with high energy tooling in confined space.

• Lack of proper reaction point for conventional tooling meant tooling would often slip adding to the danger.

• The factory specified Torque/Turn to Yield tightening method, does not achieve adequate preload for the severe service conditions.

• Inadequate preload then results in factory bolts failing in yield or fracture.

• Bolt failures often result in damage to the mounting faces necessitating expensive field machining and downtime in order to repair fretting damage.